MIXING

COMPOUNDING

Welcome to ALFA Manufacturing Group's state-of-the-art mixing department, where innovation meets precision. Featuring 16 stainless steel, jacketed mixing tanks with over 7,000 gallons of capacity - we are able to handle a wide variety of formulations with exceptional efficiency. From small pilot batches to large-scale production, our versatile mixing solutions ensure consistent, high-quality results.

Sourcing & Supply Chain

We have hundreds of raw materials in stock from all the leading specialty suppliers. Every vendor and individual material goes through a pre-screening process for approval prior to being sourced for commercial use.

Incoming Raw Materials

Upon receipt, each material is inspected and tagged for inventory traceability while being placed in quarantine. Once all necessary documents are collected and samples are taken from each lot #, the raw materials are then rigorously tested by Quality Control to ensure that they conform to set standards before they are released.

Raw Material Storage

Once raw materials have been released by QC, they are stored and inventoried in a designated area that is monitored for both temperature and humidity. Cold storage is also available for temperature sensitive materials.

Picking / Weigh Out

To prevent any possible external contamination when containers are opened, the materials are dispensed, tagged, and QC checked according to the batch ticket in our enclosed and air filtered weigh station. The materials are then palletized and labeled with the work order # prior to being staged for batching.

Cleaning & Sanitization

To ensure the integrity of each formula by preventing any cross-contamination between batches, we have engineered a proprietary cleaning and sanitization system for our tanks that allows us to dispense either a pre-rinse, Kelajet® detergent, or reverse osmosis water from a pressurized hose.

For cleaning hoses, pumps, and other equipment we use a solution containing Alcanox® detergent.

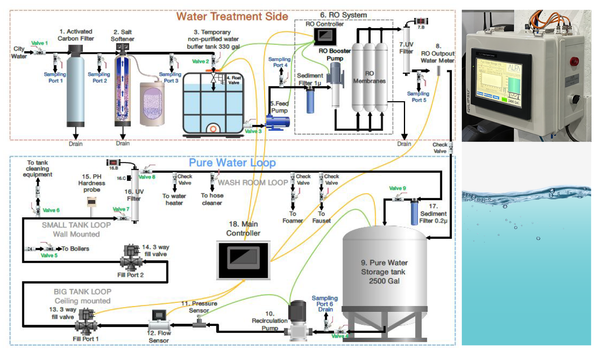

RO Water System

Given the high-percentage of water in many formulations, the quality is absolutely essential. Our digitally monitored and validated water system ensures consistent purity through a comprehensive setup that includes carbon filters, water softeners, reverse osmosis membranes, multiple UV filters, a 0.2-micron filter, and 316 stainless steel piping. It features 24-hour recirculation, air valves, and automated flow sensors for precise distribution to our mixing tanks.

BATCHING

We have over 7,000 gal of specialized mixing tank capacity spread over 16 jacketed mixing tanks ranging from 20 gal to 2,000 gal. This allows us to be flexible with the types of formulas that we can run such as hot and/or cold process batches while being able to service pilot batches to large-scale production. We also have over 15,000 gal of liquid holding tank storage available.

Quality Control

To ensure quality and consistency, each batch is tested for appearance, odor, color, pH, density, specific gravity, viscosity, and micro (TPC / yeast & mold) where the results must conform to the set standards prior to the batch being approved to fill.